James Marrow

@james_marrow

My research is focussed on the degradation of structural materials and the role of microstructure.

ID: 300195921

https://oxford.academia.edu/JamesMarrow 17-05-2011 11:07:19

96 Tweet

250 Followers

2 Following

New article from Oxford Materials: authors.elsevier.com/a/1Y6D2x-7haJAn on in situ study of damage development in a needle-stitched ceramic matrix composites

@RockSquasher Diamond Light Source Have a plan A, a plan A2, A3, Plan B, Plan B2..! Organise shifts for the team. Oh and coffee. Lots of coffee!

Do you recall the teeny-tiny fatigue crack we tweeted a little while ago? It's grown..... Diamond Light Source Oxford Materials

It moves!! This is the unique rig Oxford Materials is using to grow a fatigue crack and record high resolution tomographs Diamond Light Source

300000 more fatigue cycles and a bit more load, but we overcame 'closure'. Can you spot the difference? Oxford Materials Diamond Light Source

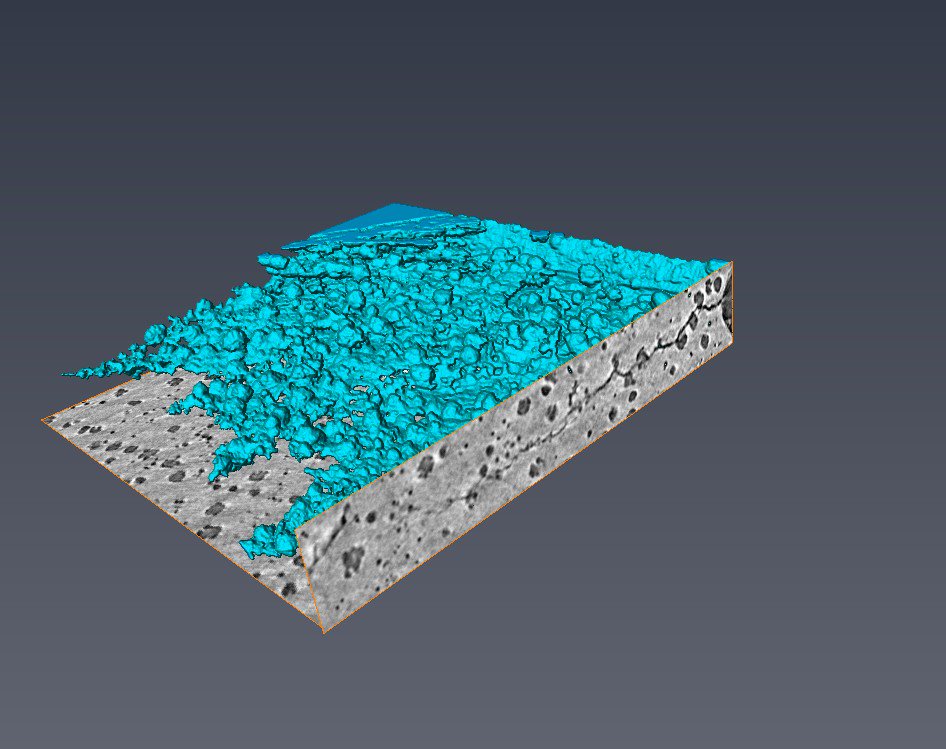

A quick visualisation of the fatigue crack we've nurtured over the past few days. Now for the analysis! Oxford Materials Diamond Light Source 😫

@mmostafavi1 Diamond Light Source James Marrow it's been great to share this unique beamline with University of Bristol team (& Tim from University of Portsmouth)

Furnace and neutron source problems... morale dropping?Oxford Materials Science and Technology Facilities Council. Science is tough, but Donuts could be the solution

#nuclear graphite at 850C, being slow loaded to investigate its strength. The donuts helped! Oxford Materials with Science and Technology Facilities Council #neutrons

Graphite cracking up at 850C. Measuring how it takes the strain with #neutrons and image analysis. Oxford Materials Science and Technology Facilities Council

#RobotWars Diamond Light Source ? No, we're investigating the toughness of natural biomaterials with #xray #tomography

Team from Oxford Materials back Diamond Light Source for another experiment on i12. We’re watching how cracks grow between the sheets in carbon-fibre composite for aerospace. We want to know how to make it tougher. Our loading rig (beige cylinder thing) is in front of the camera

Using x-ray radiographs Diamond Light Source to see the crack, which we’ll tomograph in 3D. Here’s one (just a mobile phone photo of the screen!). The sample is 0.5 mm thick, and we’ll grow the crack in steps of 40 um (less than the thickness of a human hair). Oxford Materials